Since 1990, Sunny King collaborated with the Industrial Technology Research Institute (ITRI) to develop centrifugal pump core technology. Beginning 1999, the company also participated in the ITRI’s dry vacuum pump R&D project. In recent years, the company has even adopted computerized simulation and analysis system to improve the energy efficiency and reliability of pumps. Currently, Sunny King is fully equipped to design and manufacture centrifugal pumps, gear pumps and vacuum pumps, and outfitted with ISO9906-compliant pump performance testing platform, giving it complete technical expertise ranging from basic R&D to product performance validation. Design and development is basically divided into three stages, i.e. conceptual design, preliminary design and detailed design. From the decision on basic product specifications, such as technical requirements and structural form, at the conceptual design stage to detailed dimensions and analysis of components at the detailed design stage, the company utilizes computer software and years of technical experience, combined with fluid dynamics analysis and validation, to complete product development at various stages.

Deciding on the structural form and applicable specifications of the pump. The following diagram is the conceptual design for SCH100-16.

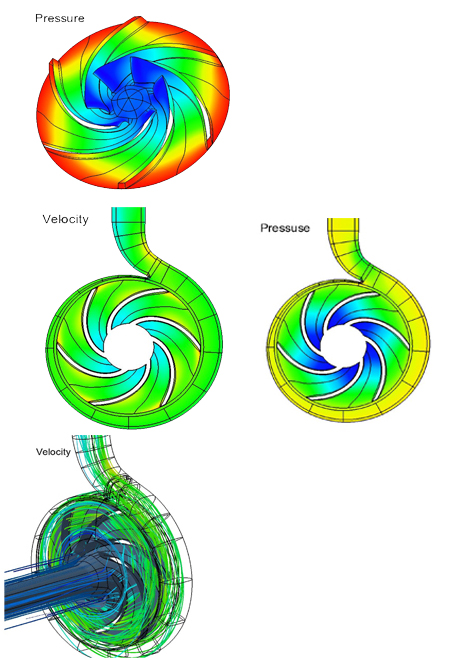

Using the designing of impeller for centrifugal pump as an example, the first step is to determine the basic design criteria for the impeller based on actual experience and mathematical modeling.

After determining the basic criteria, technical parameters related to impeller performance are keyed into the development software.

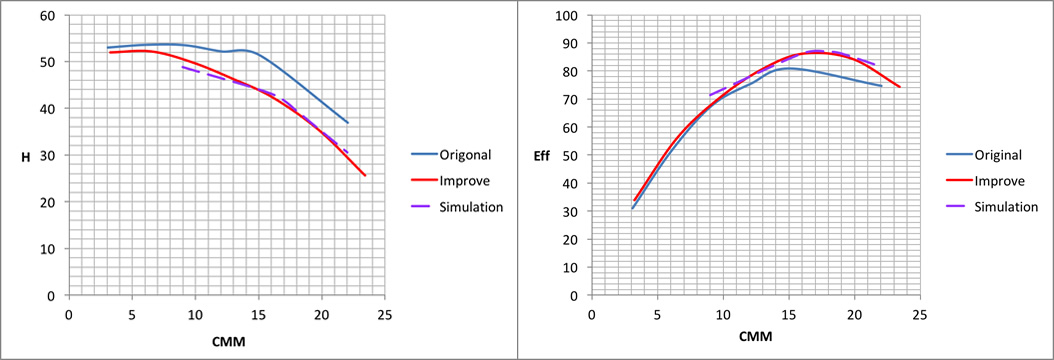

Finally, an initial software simulation of pump performance is generated to verify the feasibility of the design.

After design verification, a prototype is built and validation of its performance is conducted on site in accordance with standard test conditions. Any changes in design will be based on result of test run.